Brewers Edge Mash & Boil All Grain Brewing System Review

This review is past Homebrew Finds Contributor Brad Probert. Brad is an engineer, skillful homebrewer and experienced reviewer. Grab a link to Brad's website at the finish of this review.

Brewer's Border Mash & Eddy

I reviewed a number of electric all-in-1 brewing systems a lilliputian over a year ago. As a collective group, these systems offer a lot to the homebrewer. They provide the flexibility and control of brewing process of all-grain, and the equipment simplicity of mash-in-a-bag. The fact that they're electric gives yous the ability to brew inside and convenience of not having to hunt propane tank fill up-ups. The electrical systems also have the ability to set a target temperature and control to it, giving you better control of your mash day. All of these combine to create a more streamlined and less stressful brew day.

Each arrangement has its own strengths and they all span a broad cost range. The units I tried last year ranged from $470 at the low finish to $2,500 at the high end. When I saw the Brewer'due south Border Mash & Boil coming in at $300, I was intrigued to come across how this unit would work and if you actually could go all-grain with an electric system at such an affordable price betoken.

General Function

The Mash & Eddy (M&B) runs on 120V power, and then you lot accept wide flexibility on where yous tin employ it. 240V is definitely faster to heat and has a stronger boil, but it limits your possible brew locations. The M&B has 2 heating elements, assuasive you lot 3 different levels of heat at 600W, 1000W, or 1600W. Different than the other all-in-ane units, the One thousand&B does non have a pump for recirculating wort. This is one obvious difference from the others, but by skipping the pump, there are less parts to make clean and it keeps the price lower. The unit does accept an easy to operate spigot valve at the bottom that allows y'all to transfer wort, or manually recirculate your brew using a pitcher.

Compare Prices, Review Continues Below

- Brew and Boil at William'south Brewing

- Mash and Boil at MoreBeer

- Search Amazon for "Brewer's Border Brew and Boil" – offerings vary

There is a malt piping that sits inside like a large sleeve, with a steel simulated bottom built into it. This makes it a Brew In A Bag (BIAB) set-up where y'all pour your crushed grains into this malt pipe for mashing, and so simply raise it up out of the wort for sparging. Congenital-in feet gratis up your hands for pouring sparge h2o through information technology.

Most impressive is the double-walled primary unit body. The double wall serves many purposes similar keeping your mash at a good steady temperature without requiring continuous oestrus improver, supporting a good rolling boil with lower ability heating elements, and making your brewing surface area a bit safer past preventing inadvertent burns when you touch the outside of the unit. It also helps give the unit some robustness and strength. And unlike some other all-in one brewing units, information technology comes with welded-on handles to make transportation much easier. Sometimes the lilliputian things make a large difference.

The build quality on the K&B really is notable. In most scenarios in life, y'all go what you pay for. Yous observe something cheap, and it's typically poorly fabricated. The K&B proves that you tin't ever gauge quality by the price tag. The fit & finish of all of the parts is top notch. Things fit together well, there are design features and manufacturing processes added to ensure no sharp metal edges at seams. Welds are clean and neat. Metal gauges are all sufficient to keep things sturdy where needed and non endure bending and flexing.

Electrical Controller

The M&B has a elementary controller. It has + / – buttons to modify the ready temperature, and a very cool characteristic of being able to set a timer for when yous want it to come up on- up to 24 hours in advance. The delay timer brings in smashing options of getting your strike water to temperature while you lot're coming domicile from work, or overnight so you tin can jump right in when you get up in the morn. And everyone who brews can appreciate time-saving features that shorten your brew day!

The temperature sensor for the controller is at the lesser of the unit. This makes it prone to reading differently than the boilerplate mash temperature, and I actually found it reading a few degrees low (more than on this later). However, there are drawbacks with well-nigh anywhere you put the sensor, and this tendency to read low tin exist counteracted by circulating brew water/wort- either past stirring with a spoon, using a pitcher and the built-in spigot, or hooking upward a wort pump and a length of hose.

Hands on Trials

The more years that I brew, some parts of my beer-making process get more than complicated and need more than equipment, and others I strive to simplify. Water salt additions and multi-stride mash temperature profiles- count me in. Brewing equipment that'south complicated to clean, or requires actress trips of hauling stuff to my brew expanse- you're killing me. The M&B fits within this "brewing profile" nicely. The simplicity of the whole mash session beingness independent in one piece of equipment is great- both when information technology comes to number of trips lugging stuff around and to the clean-up at the cease.

I did meet 2 bug during my mash trials. One I was able to overcome with some inquiry/trials, and the other was a user-induced error that I programme to not brand again. First I'll comprehend the user error. I mash session I was plagued by an ER4 error code that shut me down by kicking off the heating elements and not letting them come dorsum on. One of the reasons the temperature sensor is on the bottom is to avoid someone leaving their heating elements on but with the unit dry. I wasn't running dry out, but I did spill some grains out of the malt tube during my mash. These ended up getting stuck at the bottom and scorching there (since that'south where the heating element is). This created a local hotspot that the sensor picked up on and shut down the coils. I had to transfer the batch to another vessel to finish it off, but that error wouldn't clear until I cleaned up my mess. And so I learned a valuable lesson to exist careful with my grains during mash.

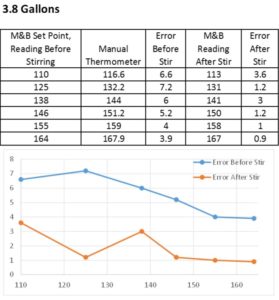

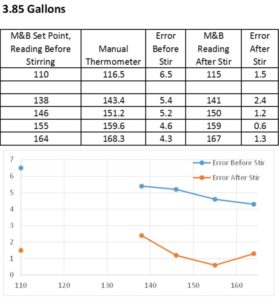

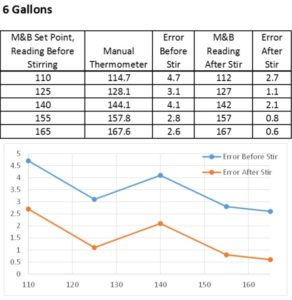

The other outcome I had that I was able to overcome was also related to the temperature sensor beingness on the bottom. During my first brew session, I monitored the temperature of my strike water and brew with my own thermometer and compared to the LED readout on the controller. I establish the LED was reading 3 – 5 degrees low. For me, a digital read-out and the power to set the temperature on the controller meant just that- I wanted to control the temperature to the degree of accuracy shown on the LED.

I did some temperature trials simulating heating strike h2o, both in a smaller book and larger book, representing a 2.five gallon batch and a 5 gallon batch of beer. I plant the aforementioned temperature mistake high like I did on my brew day, so I went about collecting data at different temperature points, to make a temperature adjustment line. Knowing that there can be significant temperature variations in continuing water, I stirred it up well while I was taking readings with my transmission thermometer. I found that just by doing this, I was able to go along the water circulating by the temperature sensor in the bottom and the LED readout came in to match my thermometer within i-2 degrees.

So I concluded I could either use my aligning line to just set my controller lower by the iii – 5 degrees, or I could circulate the water. The simplest way of class is but with a mash spoon. Another is by drawing off liquid through the spigot and pouring it in up meridian. Since I own a wort pump, I tried a 3rd method, which was to claw up my pump to the spigot with a length of high-temp hose, and then transport the output in on top of the grain bed. The pump worked pretty slick for me and I programme to become that road adjacent time. Since I already employ a pump when I use my counterflow chiller at end of brew twenty-four hours, it doesn't increase my burden of either stuff to clean or stuff to haul around.

3.eight Gallon Strike Water Trial

3.eight Gallon Strike Water Trial

3.85 Gallon Strike H2o Trial

3.85 Gallon Strike H2o Trial

6 Gallon Strike Water Trial

6 Gallon Strike Water Trial

Conclusions

My overall impression of the M&B is that it is a great unit. At the price betoken of $300, you literally can't crush it with what's on the marketplace today. And although the creator (Bill Moore) told me that it was targeted to the new brewer to make an affordable entry stride to all-grain brewing, I call up they've got something with a much broader appeal. Information technology definitely hits the marking for new brewers to go all-grain without buying extra kettles, coolers, false bottoms, etc. Just this unit of measurement is cracking even for more advanced brewers that want to apply their actress resources to petty with mash pH rather than actress hours being a dishwasher at the end of their brew day.

Compare Prices, Review Continues Below

- Mash and Boil at William'due south Brewing

- Mash and Boil at MoreBeer

- Search Amazon for "Brewer's Edge Mash and Boil" – offerings vary

More Homebrew Finds!

- Last 50 Finds!

- Meridian Deals – a curated list of the best deals

- Homebrew Reviews – one of the largest libraries of homebrew reviews in existence!

- Our Top Posts – tips, how-tos, resources posts and more

- Let'southward exist Friends!

Recent Deals!

10 Most Recent Homebrew Resource Posts & How-To's!

We are Homebrew Review HQ! Our x Most Contempo Reviews

Homebrew Reviews: Electric Brewing

Check out Brad'south website – beersnobby.com

Give thanks you to BrewCraft USA for generously providing a unit of measurement for evaluation.

Toll, promotions and availability can change chop-chop . Bank check the product folio for current price, description and availability.review:bpmandboil tag:tpr rs:5

Source: https://www.homebrewfinds.com/2017/09/hands-on-review-brewers-edge-mash-boil-electric-brewery.html

0 Response to "Brewers Edge Mash & Boil All Grain Brewing System Review"

إرسال تعليق